Boiler Water Chemicals

Boiler water treatment chemicals play a crucial role in enhancing boiler efficiency and mitigating issues such as scale accumulation, corrosion, and foaming.

These additives play a crucial role in protecting the metal elements of the boiler and facilitating effective heat transfer. Common varieties consist of oxygen scavengers, alkalinity adjusters, scale and corrosion inhibitors, and amines.

Here's a more detailed look at the different types:

Oxygen Scavengers:

Purpose: Remove oxygen that is dissolved in boiler water to prevent corrosion from occurring.

Frequently Used Chemicals:

- Sulfite base

- Hydrazine base

- DEHA (Diethylhydroxylamine) base

Alkalinity Enhancers:

- Purpose:

Adjust and maintain the pH of boiler water to prevent corrosion and scale formation.

Common Chemicals:

- Sodium hydroxide Base

- Amine Base

Scale Control Agents:

- Objective: To inhibit the accumulation of scale on boiler surfaces through protective coatings, thereby enhancing heat transfer efficiency and reducing the risk of overheating.

- Widely Used Chemicals:

ZEELCHEM Phosphates and ZEELCHEM Polymers.

Corrosion Inhibitors:

Unleashing power with elegance, the Koran Mini blends advanced engineering with classic design, delivering a thrilling ride that’s both swift and smooth.

Amines Compounds:

Aim: Counteract acidic condensate and avert corrosion in condensate pipelines.

Standard Chemicals: Morpholine

Other Compounds:

- Sludge Treatment Agents/Sludge Conditioner

Contribute to the reduction of sludge formation and keep it evenly distributed, which enhances heat transfer.

- Coagulants/Coagulating substances Facilitate the removal of suspended solids from boiler water.

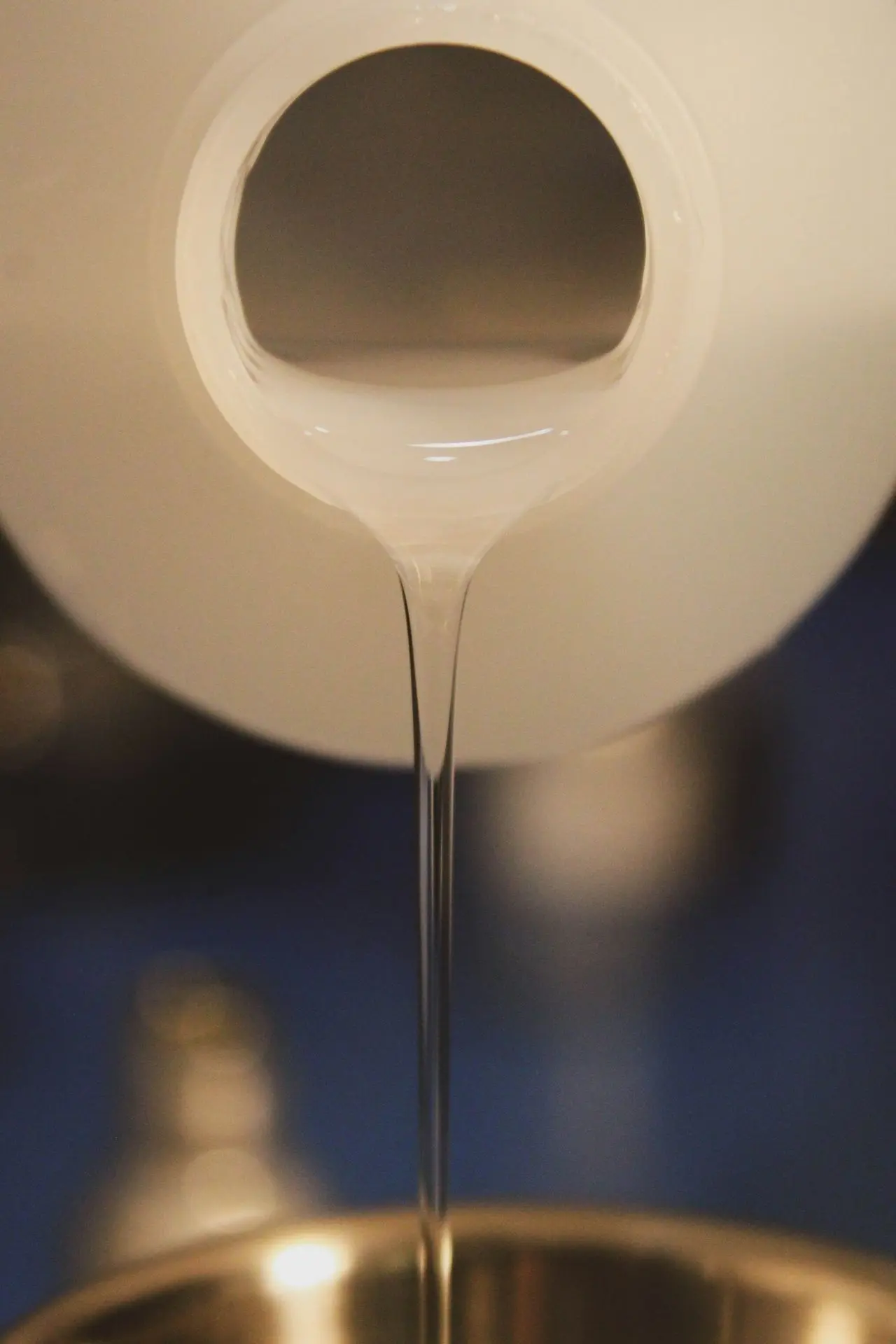

- Defoaming agents/Defoamer

Minimize foaming to prevent the migration of solids into the steam.

Crucial Aspects:

- Type of Boiler:

Different boiler systems, such as steam and hot water, might need specific chemical treatments tailored to their requirements. - Operating Pressure Level:

The pressure levels in a boiler impact the choice of chemicals and the treatment strategies applied. - Quality of Feedwater:

The properties of the feedwater, including hardness and dissolved solids, significantly affect the chemical treatment approach. - Consistent Evaluation:

Consistently analyzing boiler water and condensate is essential for tracking water chemistry and ensuring effective treatment. - Professional Advice:

It is advisable to consult a water treatment expert to identify the most suitable chemical treatment strategy for your particular boiler system.